As investment in rail infrastructure begins to accelerate via Network Rail’s £45-billion of CP7 funding, 75% of which will be spent on maintenance and renewal projects, Naylor explains why drainage is now a core focus for the rail industry and why it’s finally being recognised for the vital role it plays in ensuring the safety of the rail network.

Source: Modern Railways. Faulty drainage that caused a landslide and claimed 3 lives in a train derailment at Carmont.

Drainage has been an age-old problem for network operators causing soft spots in track stability and effecting the maximum safe speed at which trains can operate but the full impact of poor drainage was not fully understood and in fact, for many years, drainage was seen as a relatively low-priority, commodity product by the rail industry. That all changed in 2020.

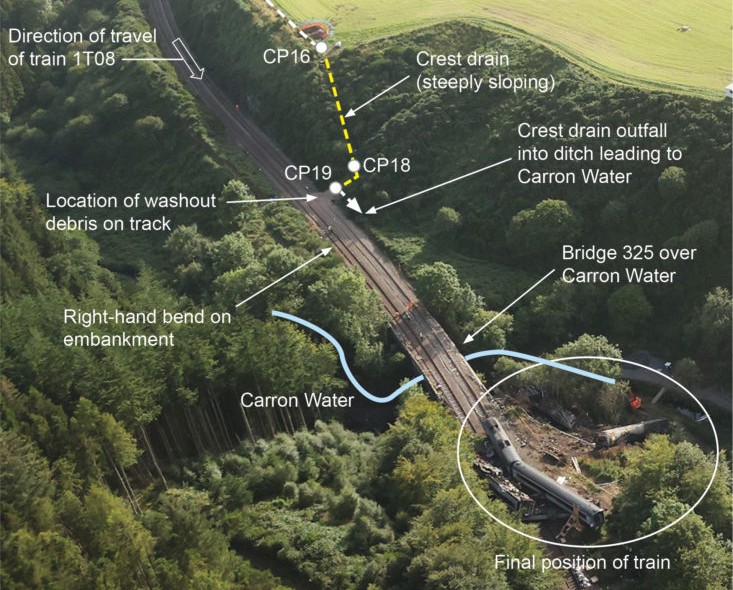

On 12 August that year, after a period of extreme and torrential rainfall, the Aberdeen to Glasgow train derailed at Carmont near Stonehaven, Aberdeenshire resulting in the deaths of three men and injury to its six passengers.

Having left the track, the train collided with a bridge parapet which caused the train to veer off the bridge and down the steep embankment below the bridge. The subsequent investigation found that the derailment of the train, which had already been prevented from completing its journey south because of a landslip south of Carmount, was caused by gravel and other stony debris being washed out of a drain and onto the track. In effect, a drainage failure.

A joint investigation by Police Scotland, British Transport Police and the Office of Rail and Road (ORR) under the direction of Crown Office and the Procurator Fiscal Service[i] and the related 2022 report highlighted three key issues: Network Rail failed to ensure that its contractor had built the drain in accordance with the approved design; it had not inspected the whole drain since its construction, and its staff had not been comprehensively trained to effectively analyse weather forecasts or in how to use all available weather data resources - an important factor as high intensity rainfall events, which make mitigating flood risks a priority, are becoming increasingly common.

With the ongoing impact of climate change and more recently recorded incidents on the rail network, a much more robust approach to water management is now been adopted and drainage has become a significant area of focus for Britain’s rail industry. As one major rail contractor, Balfour Beatty, comments: “Drainage is now the biggest issue for the rail network to resolve.”

Falling under Network Rail’s ‘Core Assets Renewals’ segment of CP7 expenditure which totals more than £19bn, drainage is now valued for the impact it has on network efficiency, costs and importantly, passenger safety – a core area of focus for CP7. Addressing the issues around drainage is seen as a particularly pressing concern because of the effects of climate change[ii].

Network Rail for its part is taking drainage very seriously. It has set up a ‘specialist drainage group’, has published a challenge statement with regard to drainage which summarises the need for better drainage and the issues faced[iii], and now routinely conducts drainage assessments across its network. As an industry, the construction products sector and its merchant partners also have a role to play.

Following changes to the product approval processes used within the rail industry, the need for PADS approval on drainage products has now been removed and as a result, the engineering community is now responsible for drainage design. This means engineers are now able to focus on product performance rather than having to use what some rail engineers considered to be a restricted list of approved products.

As a result, drainage, culverts and other assets are now being designed to assume that major storms or rainfall events will occur on an annual basis and not once in every 50 years, the previous design requirement.

The move away from PADS approval will also give the understandably risk-adverse rail industry the opportunity to access drainage and water management systems which have been tried and tested in similar applications such as highways, an area where Naylor has a strong track record with products including Naylor’s popular ‘MetroDrain’ system which is ranked number one by National Highways and its ‘AquaVoid’ water attenuation system which is designed specifically to deal with stormwater at or near to its source.

|  |

It also means that drainage manufacturers and their merchant partners are now in a position to give the rail sector informed specification guidance based on the full range of drainage and flood management systems which are available for them to use, and importantly their in-situ performance in rail and related applications.

Our hope at Naylor is that this, coupled with the strong focus on drainage within CP7, will help drive the specification of future-proofed, high performance drainage solutions in the rail industry which will enhance the safety and operating efficiency of our rail network, and ultimately benefit us all.

[i] https://www.copfs.gov.uk/about-copfs/news/rail-company-sentenced-for-fatal-crash-and-fatal-accident-inquiry-decision/

[ii] https://www-smartinfrastructure.eng.cam.ac.uk/news/network-rails-cp7-elevates-drainage-investment-response-task-force-review-aiming-mitigate

[iii] https://www.networkrail.co.uk/wp-content/uploads/2019/06/Challenge-Statement-Drainage-Efficient-and-effective-drainage-interventions.pdf